BENDING / ROLLING

Our press brakes are equipped to handle large capacities.

Bending of flat parts

From small, precise components to large construction elements, our machines guarantee the utmost precision. The cut parts are carefully bended according to detailed working drawings drawn up by our own engineering office. This ensures a seamless integration of design and production. In the group we have 8 bending machines at our disposal with which we bend workpieces in different qualities. with max dimensions up to 7.1m and maximum bending force up to 640 tons.

We have the possibilities to bend very complex geometries of workpieces thanks to our two Gooseneck upper blocks.

- Maximum dimensions up to 7.1m

- Maximum bending force up to 640 tons

- Gooseneck top blocks for bending complex geometries

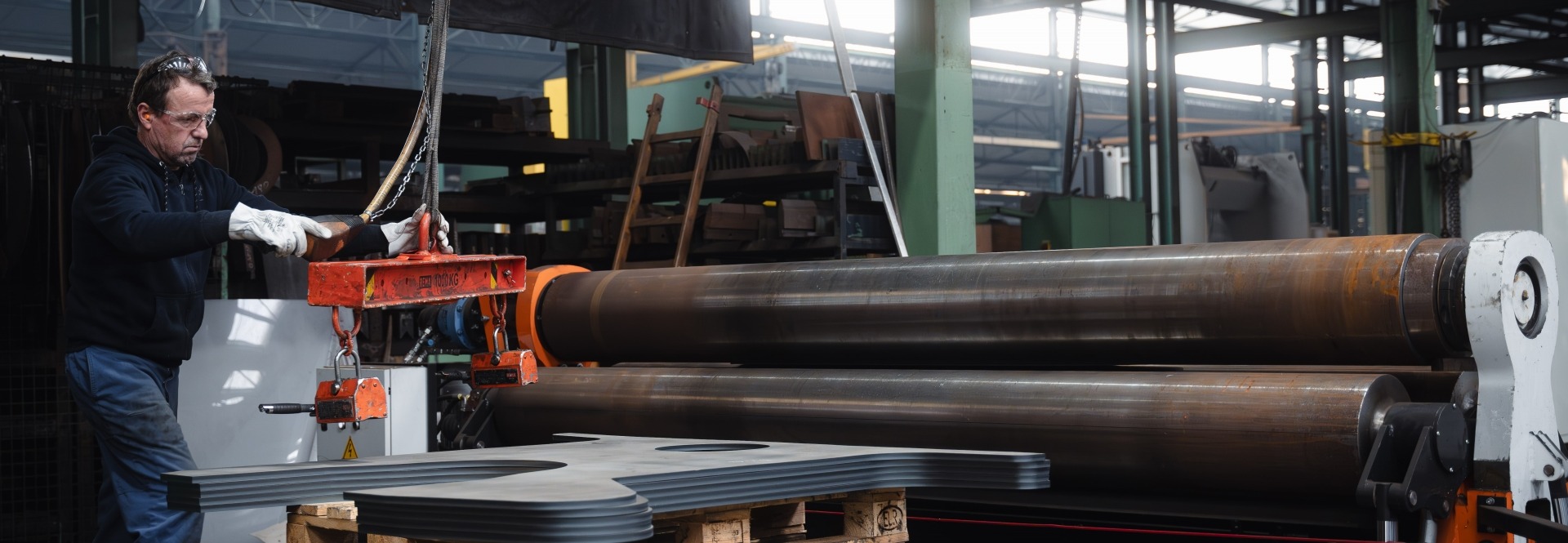

Flat rolling and round rolling

During the bending process, we perform strict quality controls to ensure that each piece meets the highest standards of dimensional stability and quality. In order to eliminate the distortion after high-tensile cutting, we have a flattening mill at our disposal to get the workpieces within the required flatness for further processing in the production process. In addition, we also have a rounding mill at our disposal with which we can produce workpieces with a large radius.

- Flat rolling: plate thicknesses up to 25mm

- Round roller: plate thicknesses up to 12mm

SECTORS

- agriculture

- textile machinery

- power supply

- railway

- energy

- handling and transport

- defense

- recycling

- mining

Looking for a partner for bending complex parts?

Please feel free to contact us here.